You are currently viewing documentation for CompuTec ProcessForce 2.0, which is still supported.

We recommend upgrading to CompuTec ProcessForce 3.0, which is a plugin installed and managed through CompuTec AppEngine 3.0, built on .NET 8.

However, please note that CompuTec AppEngine 3.0 has a different architecture, and all CompuTec components, including the CompuTec ProcessForce 3.0 plugin, need to be updated together to ensure full compatibility.

Before starting your installation or upgrade process, we strongly recommend reviewing the CompuTec AppEngine 3.0 and CompuTec ProcessForce 3.0 documentation.

Yield Analysis

Yield Analysis is a crucial aspect of production monitoring in CompuTec ProcessForce, helping manufacturers assess efficiency by comparing planned and actual production outcomes. The analysis can be simple, such as a basic Planned vs. Actual quantity comparison, or detailed, evaluating specific material usage across Parent Items, CoProducts, ByProducts, and Scrap.

Yield Analysis Examples

The table below provides examples of different yield calculation methods, illustrating how various components contribute to yield efficiency.

| Yield Basis | Yield Calculation | Example |

|---|---|---|

| Item Parent | Item Parent | Item Parent Actual Quantity / Item Parent Planned Quantity * 100 |

| Item Parent | Item Parent + CoProducts + Scrap | (Item Parent Actual Quantity + CoProducts Actual Quantity + Scrap Actual Quantity) / Item Parent Planned Quantity * 100 |

| Item Parent | Item Parent + CoProducts - Scrap | (Item Parent Actual Quantity + CoProducts Actual Quantity - Scrap Actual Quantity) / Item Parent Planned Quantity * 100 |

| Item Parent | Item Parent - CoProducts - Scrap | (Item Parent Actual Quantity - CoProducts Actual Quantity - Scrap Actual Quantity) / Item Parent Planned Quantity * 100 |

| Item Parent | CoProducts + Scrap | (CoProducts Actual Quantity + Scrap Actual Quantity) / Item Parent Planned Quantity * 100 |

| Item Parent | CoProducts - Scrap | (CoProducts Actual Quantity - Scrap Actual Quantity) / Item Parent Planned Quantity * 100 |

| Specific Item | Item Parent | Item Parent Actual Quantity / Specific Item Actual Quantity * 100 |

| Specific Item | Item Parent + CoProducts + Scrap | (Item Parent Actual Quantity + CoProducts Actual Quantity + Scrap Actual Quantity) / Specific Item Actual Quantity * 100 |

| Specific Item | Item Parent + CoProducts - Scrap | (Item Parent Actual Quantity + CoProducts Actual Quantity - Scrap Actual Quantity) / Specific Item Actual Quantity * 100 |

| Specific Item | Item Parent - CoProducts - Scrap | (Item Parent Actual Quantity - CoProducts Actual Quantity - Scrap Actual Quantity) / Specific Item Actual Quantity * 100 |

| Specific Item | CoProducts + Scrap | (CoProducts Actual Quantity + Scrap Actual Quantity) / Specific Item Actual Quantity * 100 |

| Specific Item | CoProducts - Scrap | (CoProducts Actual Quantity - Scrap Actual Quantity) / Specific Item Actual Quantity * 100 |

| All Items | Item Parent | Item Parent Actual Quantity / All Item Actual Quantity * 100 |

| All Items | Item Parent + CoProducts + Scrap | (Item Parent Actual Quantity + CoProducts Actual Quantity + Scrap Actual Quantity) / All Item Actual Quantity * 100 |

| All Items | Item Parent + CoProducts - Scrap | (Item Parent Actual Quantity + CoProducts Actual Quantity - Scrap Actual Quantity) / All Item Actual Quantity * 100 |

| All Items | Item Parent - CoProducts - Scrap | (Item Parent Actual Quantity - CoProducts Actual Quantity - Scrap Actual Quantity) / All Item Actual Quantity * 100 |

| All Items | CoProducts + Scrap | (CoProducts Actual Quantity + Scrap Actual Quantity) / All Item Actual Quantity * 100 |

| All Items | CoProducts - Scrap | (CoProducts Actual Quantity - Scrap Actual Quantity) / All Item Actual Quantity * 100 |

Yield Formulas

Please check the Yield settings for default formulas.

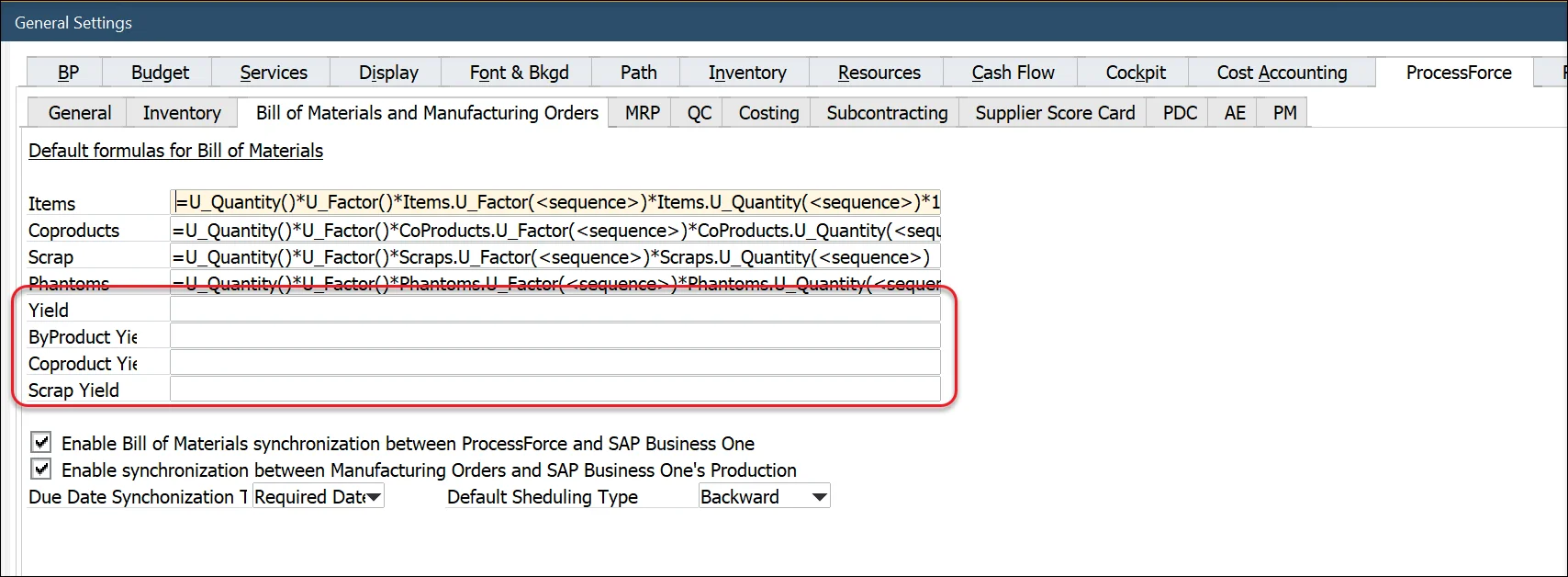

Within the General Settings form → ProcessForce tab → Bill of Materials and Manufacturing Orders tab, four additional default formulas have been added:

- Yield,

- CoProduct Yield,

- ByProduct Yield,

- Scrap Yield.

Once configured, these formulas are applied automatically within the Bill of Materials (BOM) and Manufacturing Orders (MO).

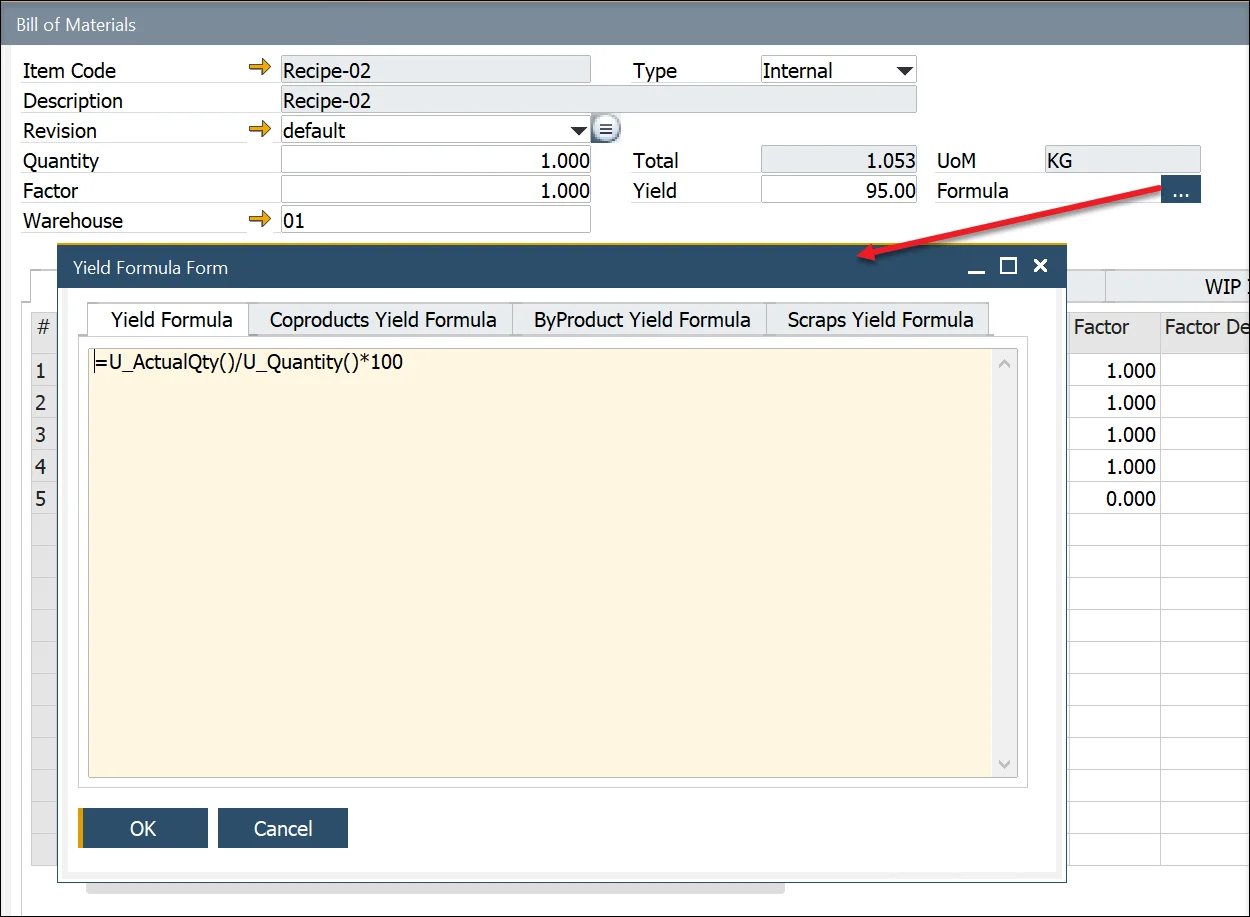

To view, create, or modify a Yield Formula, click the yellow button in the BOM form to open the Yield Formula Form:

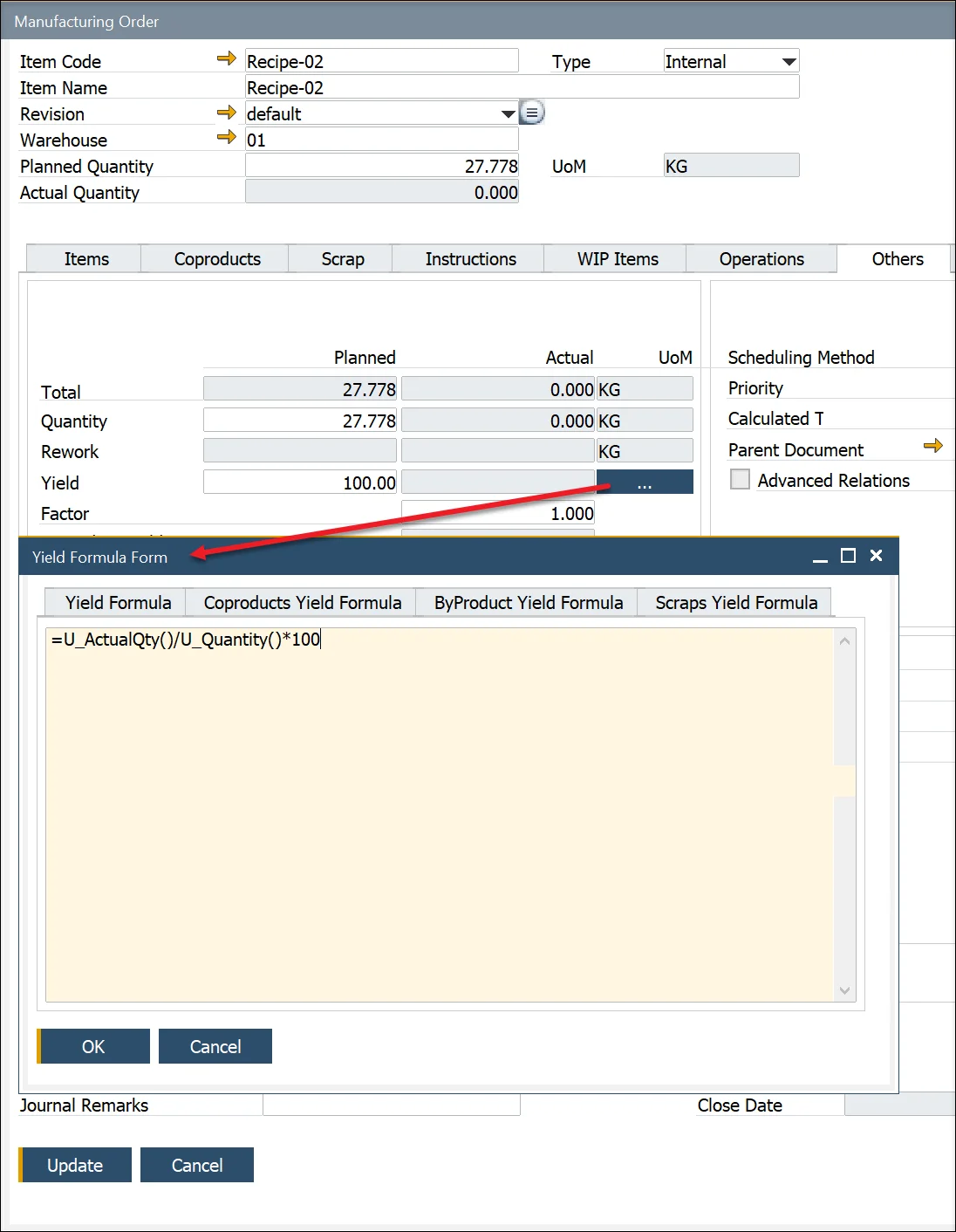

The Yield Formulas defined within the Bill of Material form are also copied to the Manufacturing Order form and displayed by clicking on the yellow button.If required, the Yield Formulas can be edited.

Yield Formula Formats

Below are examples of different yield analysis formulas:

| Yield Type | Default Description | Default Formula |

|---|---|---|

| Yield | Item Parent Actual Quantity / Item Parent Planned Quantity * 100 | =U_ActualQty()/U_Quantity()*100 |

| CoProduct | Total CoProduct Actual Quantity / Total CoProduct Planned Quantity * 100 | =Coproducts.U_ActualQty.Sum()/if(Coproducts.U_Result.Sum()=0;1;Coproducts.U_Result.Sum())*100 |

| ByProduct | Total ByProduct Actual Quantity / Total ByProduct Planned Quantity * 100 | =Scraps.U_ActualQty.Sum(equals(Scraps.U_Type();"Usefull"))/if(Scraps.U_Result.Sum(equals(Scraps.U_Type();"Usefull"))=0;1;Scraps.U_Result.Sum(equals(Scraps.U_Type();"Usefull")))*100 |

| Scrap | Total Scrap Actual Quantity / Total Scrap Planned Quantity * 100 | =Scraps.U_ActualQty.Sum()/if(Scraps.U_Result.Sum()=0;1;Scraps.U_Result.Sum())*100 |